The Fluid Eye® Model

Optimize lubrication. Minimize cost and CO₂. Maximize reliability.

Fluid Eye® is the world’s first Operating System for Lubricants — managing the full lifecycle of industrial fluids to deliver measurable performance, savings and sustainability.

Our proven 3-step model helps companies cut downtime and costs, extend fluid life and reach Net Zero Lubrication.

Step 1: Plan with Insight

Smarter lubrication starts before a single drop is used.

Fluid Eye® Insight uses real data and advanced simulations to build a lubrication strategy aligned with your assets, goals and budgets.

Value Simulation

Model fluid life, maintenance intervals and failure risks

Compare alternative strategies and forecast costs & emissions

Identify where the biggest savings and sustainability gains can be made

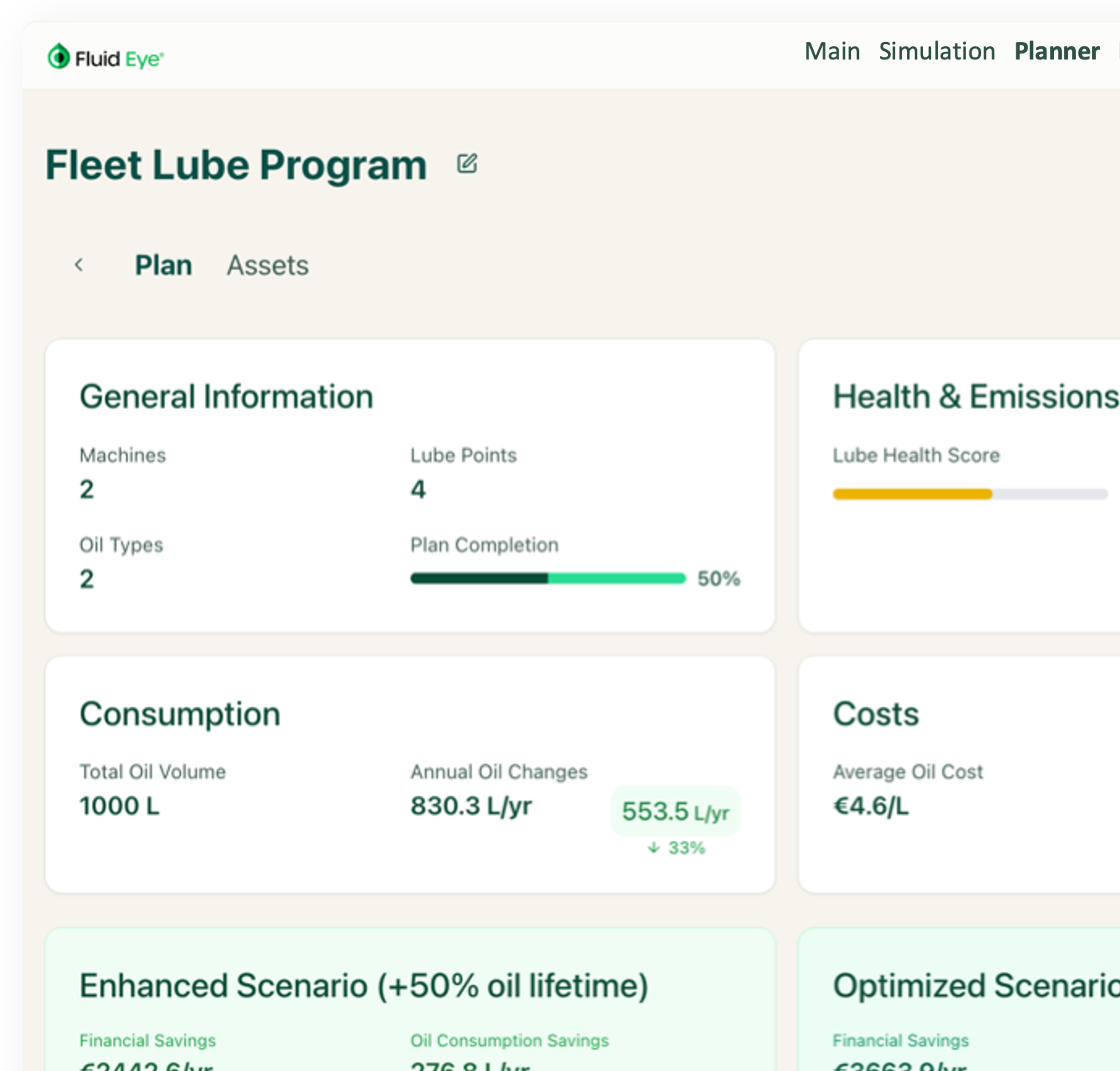

Lube Planning

Structure lubrication programs based on machine and lab data

Set targets with simulation-backed insights

Align planning across the entire site, fleet or operation

Step 2: Perform with Precision

Keep fluids - and machines - in peak condition.

With continuous monitoring and expert optimization tools, Fluid Eye® helps maximize uptime, extend fluid life and improve TCO.

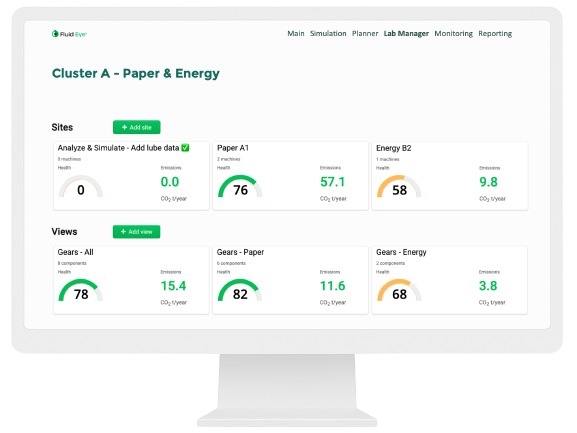

Lab & Oil Data Manager

Turn lab reports into scores and actions

Visualize trends and benchmark condition across fleets

Improve decisions with clear guidance and tracking

Connected Oil® Monitoring

24/7 diagnostics, alerts and expert advice

Detect anomalies early and avoid failures

Extend oil life and machine health

Lube Optimization

Remove impurities and prevent oil aging

Strengthen fluids with additives and premium oils

Access lab services, projects and diagnostics anytime

Close the loop. Prove the results.

Fluid Eye® Recover & Report makes the lifecycle circular — enabling smarter end-of-life decisions, regeneration and certified emissions tracking.

Recovery & Regeneration

Identify the best used oil recovery or disposal path

Activate regeneration services and offset CO₂ with credits

Plan continuity with full lifecycle perspective

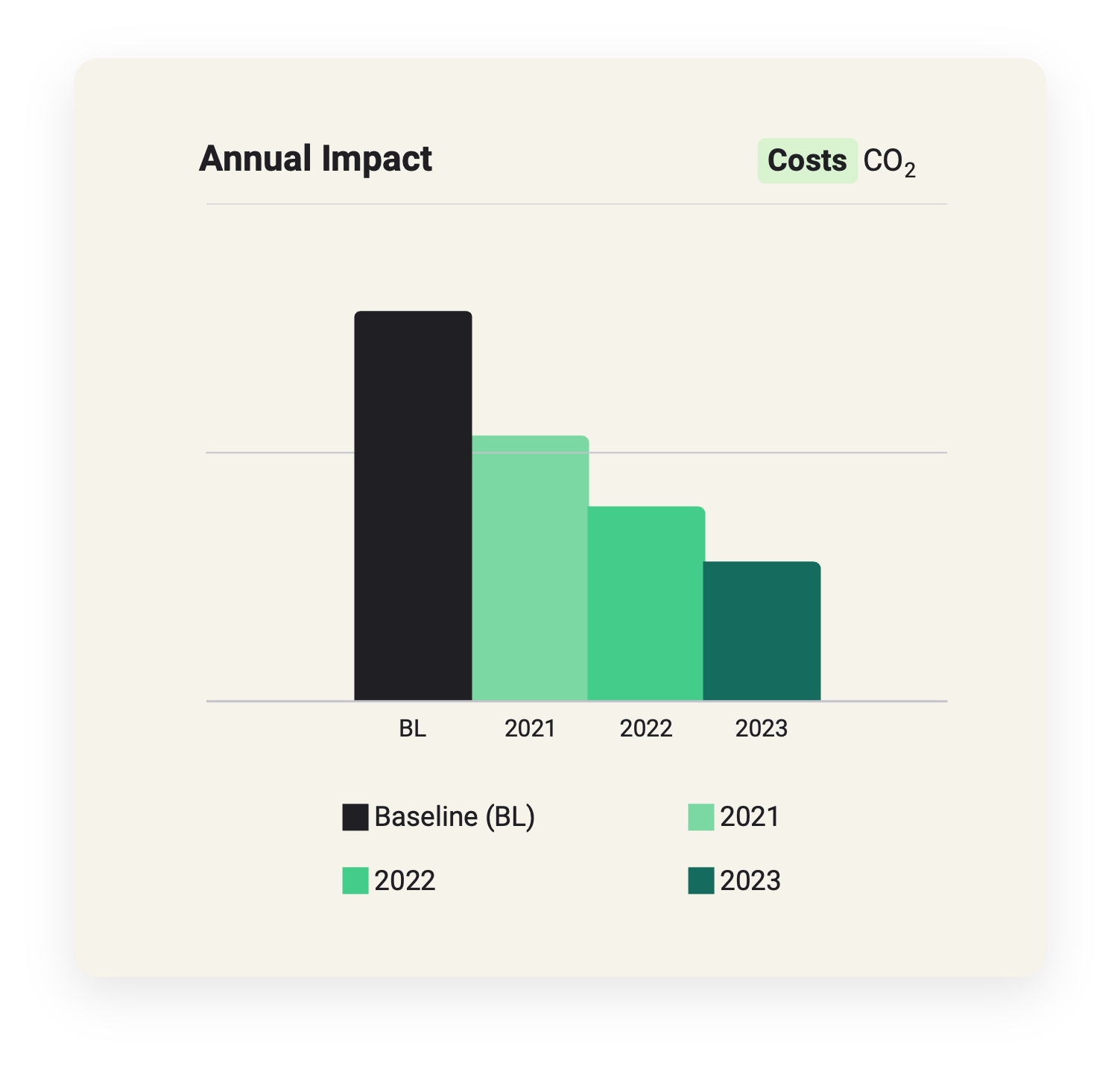

Reporting & Compliance

Automate cost, reliability and CO₂ tracking

Visualize trends and prove improvements site-wide

Fulfill Scope 1–3 reporting with audit-ready documentation

Step 3: Extend the Impact

Why it Matters

Every year, global industries lose over $1 trillion to downtime, failures and excessive oil consumption. Over half of this is linked to lubrication.

The Fluid Eye® Model addresses this head-on — delivering higher uptime, lower costs, and measurable emissions reductions.

Ready to Transform Your Lubrication Strategy?

Talk to our team to see how Fluid Eye® can deliver measurable results for your operations.