Connected Oil® Monitoring

Real-time lubrication condition monitoring - for uptime, reliability and lower maintenance costs.

Why it Matters

Stay ahead of wear, failure and downtime

Lubricants are often the earliest indicators of machinery stress, contamination or wear. When lubrication is managed reactively, issues are detected too late — leading to costly downtime, unplanned maintenance, and shorter fluid life.

With Fluid Eye® Connected Oil® Monitoring, you gain 24/7 visibility into oil condition, contamination levels, temperature, and chemistry — raising alerts early and enabling proactive maintenance that protects uptime.

Prevent failures through continuous diagnostics and anomaly alerts

Extend fluid life and reduce unnecessary replacements

Maximize uptime with proactive monitoring and expert advice

Reduce total ownership costs by minimizing downtime and maintenance

“Applying proactive fluid performance monitoring and oil-reconditioning has been simple and cost-effective.“

Miikka Nurmi, Operation Manager

How it Works

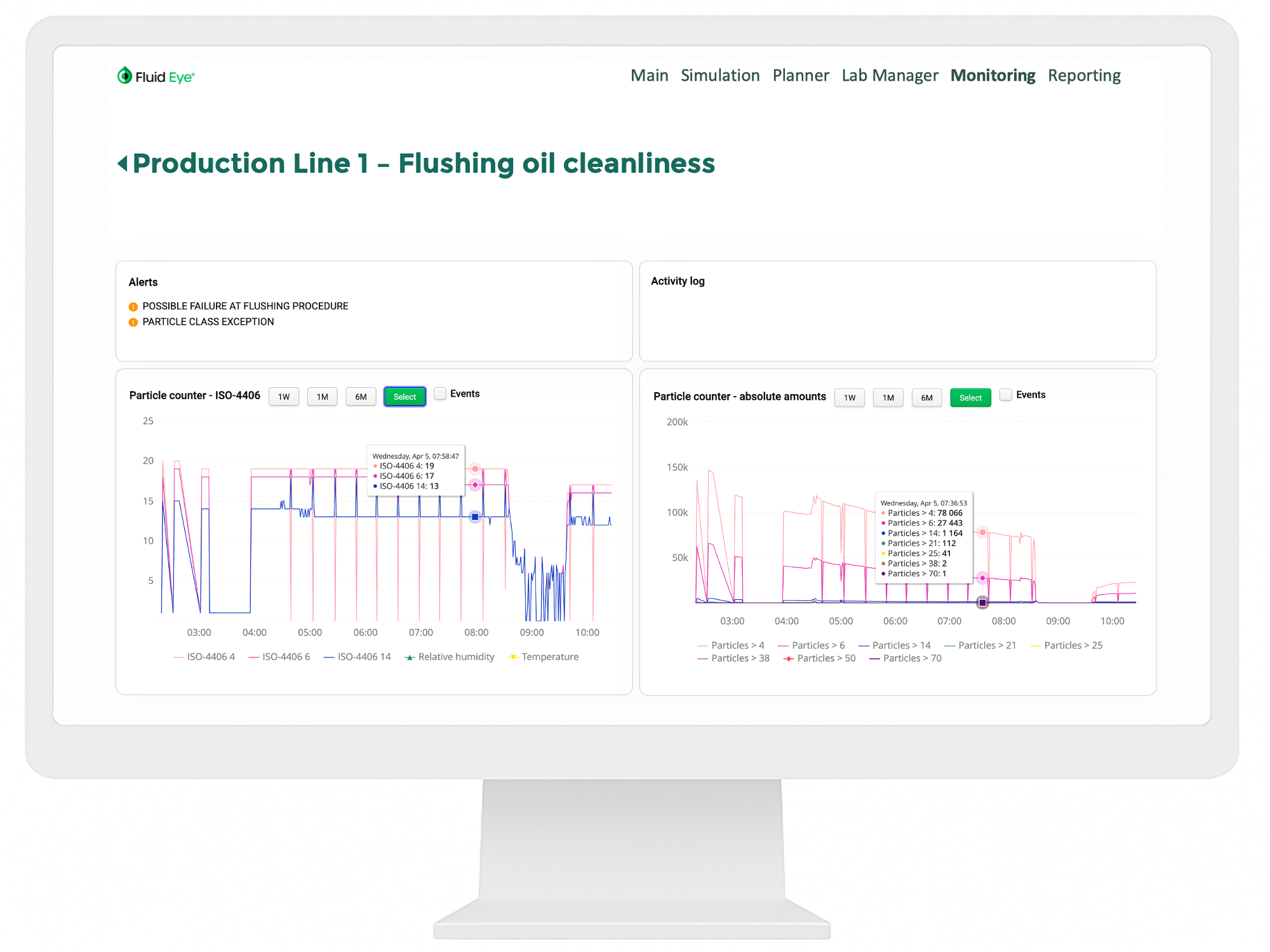

Connected Oil® Monitoring - Automated & Actionable

Connected Oil® combines IIoT sensors, edge connectivity and AI-powered analytics into one seamless solution.

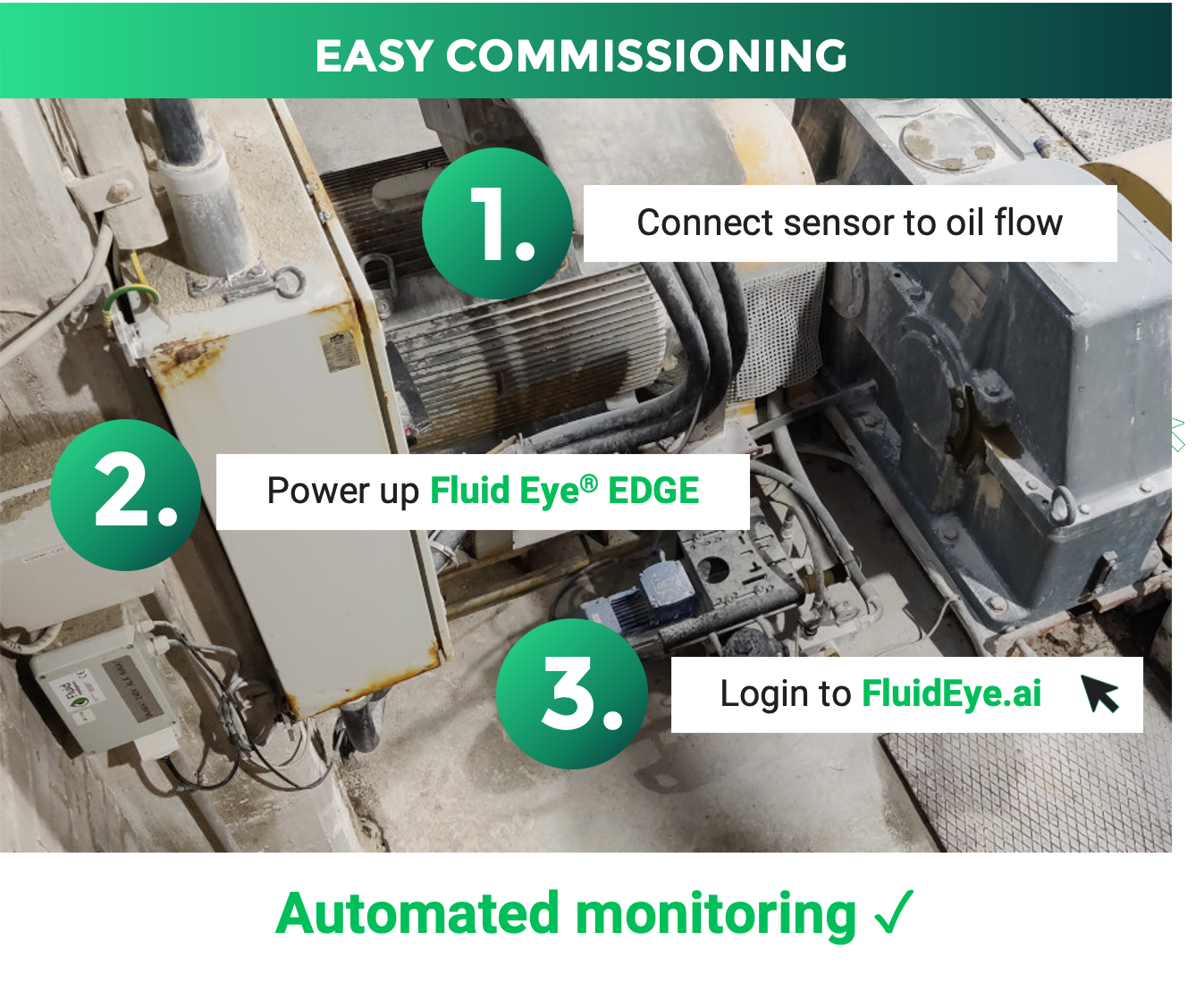

Here’s how it works:

1. Smart sensors monitor oil 24/7

Measure oil quality, cleanliness and chemical condition in real time — across lubrication systems, gears, hydraulics and more.

2. Data flows securely to the cloud

Fluid Eye® EDGE transmits the data with optimized connectivity (4G / WiFi) — no manual uploads, no gaps.

3. AI delivers Actionable Advice

Cloud analytics detect trends, anomalies and risks with multi-parameter correlation — giving you alerts and clear guidance, instantly.

→ All data and insights are visualized in Fluid Eye® — together with lab results and planning tools.

Monitoring packages

Oil Quality Trend

Tracks oil quality (OQ) and temperature

Complement with pressure, flow and tank level measurement

Cleanliness Monitoring

Measures particle counts & sizes, Particle classes & Humidity (rH%)

Combine with OQ Trend and Chemical Analysis

Chemical Analysis

Detects water (ppm), oxidation levels, antioxidant depletion, TAN/TBN & viscosity changes

Combine with OQ Trend and Cleanliness

Custom Parameters

Configurable tracking for varnish, additive depletion, mechanical indicators, and more

Integration to existing CMMS systems

Benefits in Action

Turn diagnostics into operational results

Continual analysis identifies trends and correlations in oil performance — turning technical data into clear operational decisions that improve uptime, reduce costs and extend fluid life.

24/7 visibility across critical assets

Extended oil lifetimes and sampling intervals

Fewer downtimes and machine failures

Reduced total cost of ownership (TCO)

But the impact goes further. Real-time performance data also supports sustainability — enabling smarter service intervals, longer lubricant use, and automated Scope 1–3 emissions reporting.

With Connected Oil® Monitoring, teams can act on both operational needs and Net Zero goals — in one integrated platform.

Explore how 24/7 monitoring cuts unplanned downtime →

“Oil performance monitoring brings us real operational reliability and reduces our cost base.”

Ville Vesterinen, Technical Development Manager

“Fluid Eye® Trend has increased reliability through real-time visibility to the process critical turbine oil’s performance.”

Toni Jokela, Power Plant Manager

Scalability

Monitoring that scales across fluids, systems and industries

Connected Oil® is designed to scale effortlessly across systems, fluid types and industries — supporting diverse maintenance needs from manufacturing to utilities.

Applicable equipment

Lubrication systems

Industrial Gears

Engines

Stationary Hydraulics

Mobile hydraulics

Transformers

+ Other fluid using equipment

Applicable fluid types

Lubricants

Transformer oils

Hydraulic oils

Bio-based lubricants

Additives, chemical enhancers

Fuels and bio-based fuels

Coolants, Solvents and Water

Monitored phenomena

Fluid quality and temperature

Mechanical failure indicators

Cleanliness classification and contaminants

Fluid aging and Oxidation

Varnish

Additive depletion

+ Other custom phenomena

Ready to monitor oil condition around the clock?

Talk to our experts to unlock oil condition monitoring benefits to your organization.