Lab & Oil Data Manager

Consolidate lab results, asset data and fluid health insights - for smarter diagnostics, planning and reporting.

Why it Matters

Smarter diagnostics and longer fluid life - across the fleet

When oil samples are collected and analyzed, the results often live in static PDFs or scattered folders. This makes it difficult to detect early warning signs, benchmark sites, or take timely action.

With Fluid Eye® Lab & Oil Data Manager, lab results, sampling plans, and asset diagnostics are all integrated into one system. The result? Faster decisions, fewer failures, and smarter fluid management at scale.

Benefits:

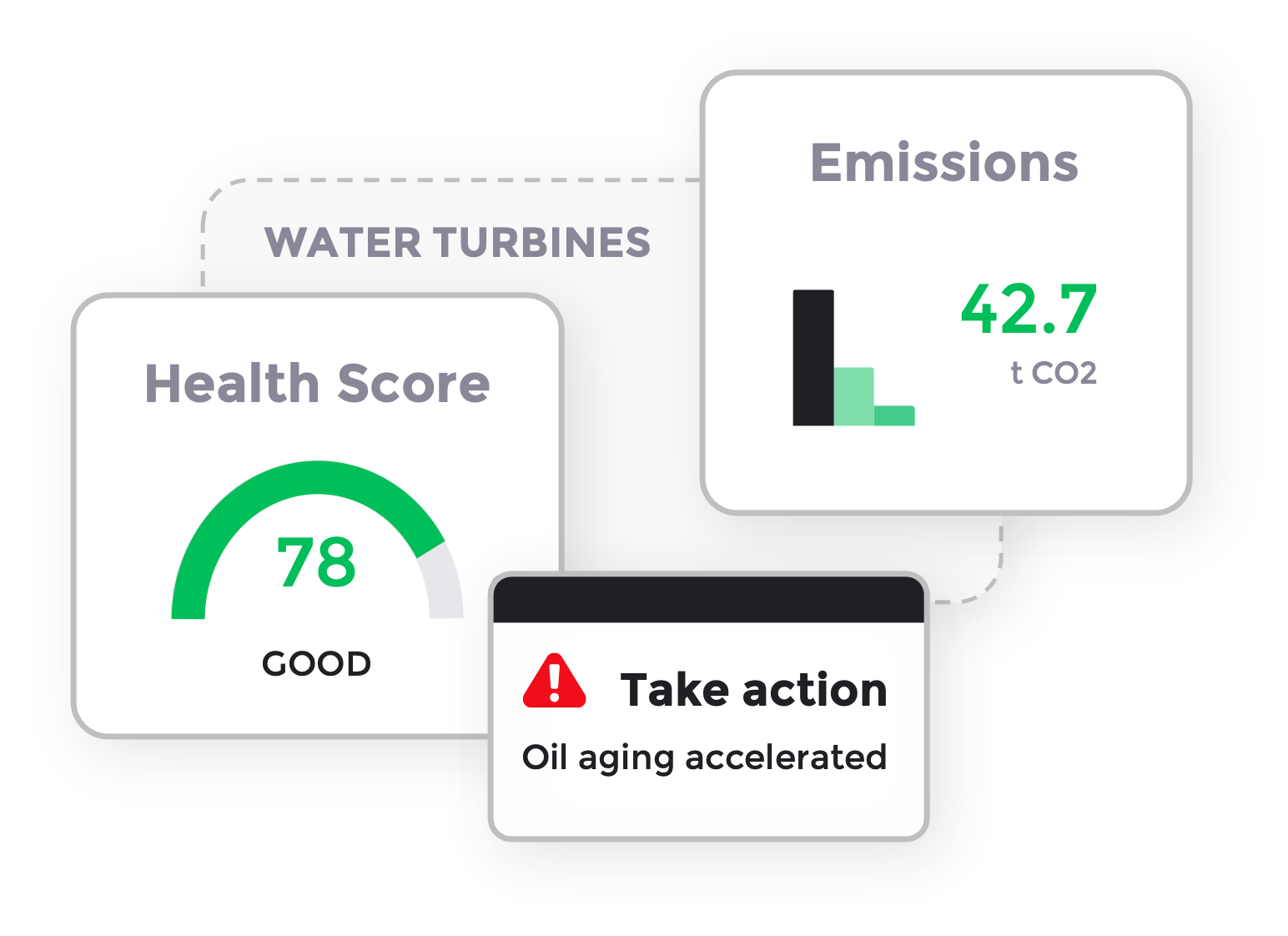

Identify oil and machine issues earlier with trend views and alerts

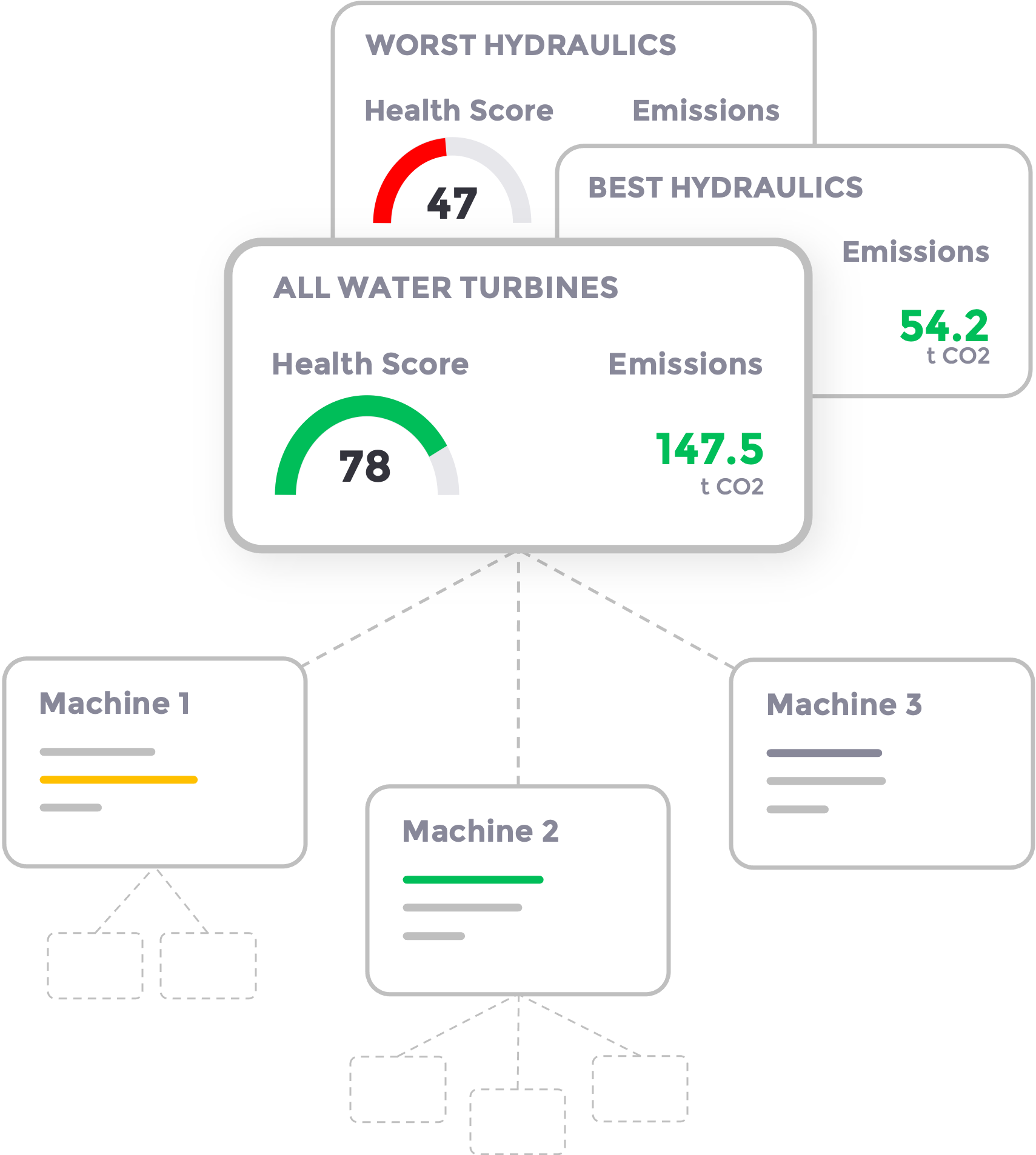

Benchmark fluid health across sites and asset types

Eliminate silos and manual work in sample collection & reporting

See how this works with Connected Oil® Monitoring →

How it Works

Integrated lab data. Actionable insights.

Lab & Oil Data Manager brings structure and intelligence to lab diagnostics with three core tools:

Sample Manager

Schedule, assign and track oil samples across teams and assets

Health Scores

Standardized condition scoring based on chemistry, cleanliness and anomalies

Dashboard & Alerts

Visualize trends, compare benchmarks, trigger follow-up actions

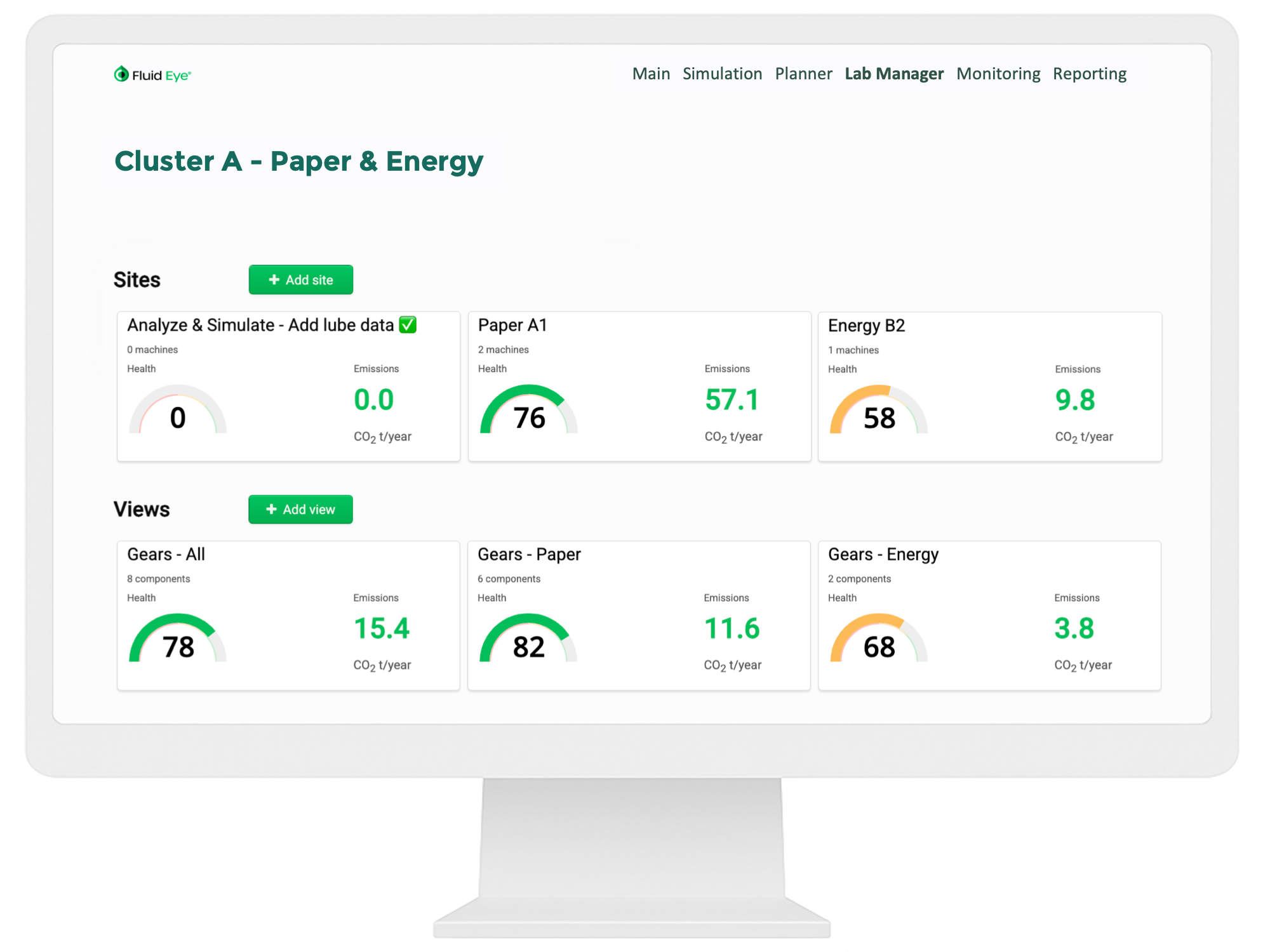

Other capabilities include: timeline logging of oil events, automated reporting, and fleet-wide views — with the option to create custom “virtual fleets” for dynamic comparison and benchmarking.

Sampling data is linked with planning and monitoring, ensuring that diagnostics guide action — not just reporting.

“Oil health management is a reliable method to ensure stable, trouble-free operation.”

Markus Lehti, Maintenance Engineer, Keravan Lämpövoima

Extend the Impact

From fragmented reporting to fleet-wide optimization

Lab & Oil Data Manager is built for scale, supporting fleets, plants and global operations with:

Centralized tracking of all sample results, from lab and online sensors

Automatic health scoring with clear alerts and guided follow-up actions

Streamlined reporting for fluid health, costs and emissions (Scope 1–3 ready)

Improved uptime and ROI with simplified compliance across sites

→ See how companies are turning oil analysis into measurable savings and longer machine life

Ready to turn oil diagnostics into performance insights?

Talk to our team to see how Fluid Eye® can deliver measurable results for your operations.