Oil Analysis for Industrial Reliability

Data-driven oil analysis and lifecycle intelligence for critical industrial assets.

Comprehensive oil analysis and digital data management give you a complete view of lubricant health, equipment condition, and lifecycle performance.

Why it Matters

Oil Analysis Is One of the Most Effective Ways to Prevent Equipment Failures

Oil is often the first indicator of wear, contamination, or lubrication-related issues. Properly interpreted oil analysis reveals developing risks long before they lead to costly downtime.

We go beyond laboratory numbers. Our approach combines:

Chemical condition analysis

Contamination and cleanliness assessment

Wear particle evaluation

Expert performance statements with clear action recommendations

Oil analysis becomes a decision-making tool — not just a report.

“Oil health management is a reliable method to ensure stable, trouble-free operation.”

Markus Lehti, Maintenance Engineer, Keravan Lämpövoima

How it Works

Comprehensive Oil Laboratory Services for Industrial Needs

Our oil analysis and lubricant lifecycle management are built around three complementary service areas. These solutions can be implemented individually or combined, depending on the specific requirements and criticality of the asset.

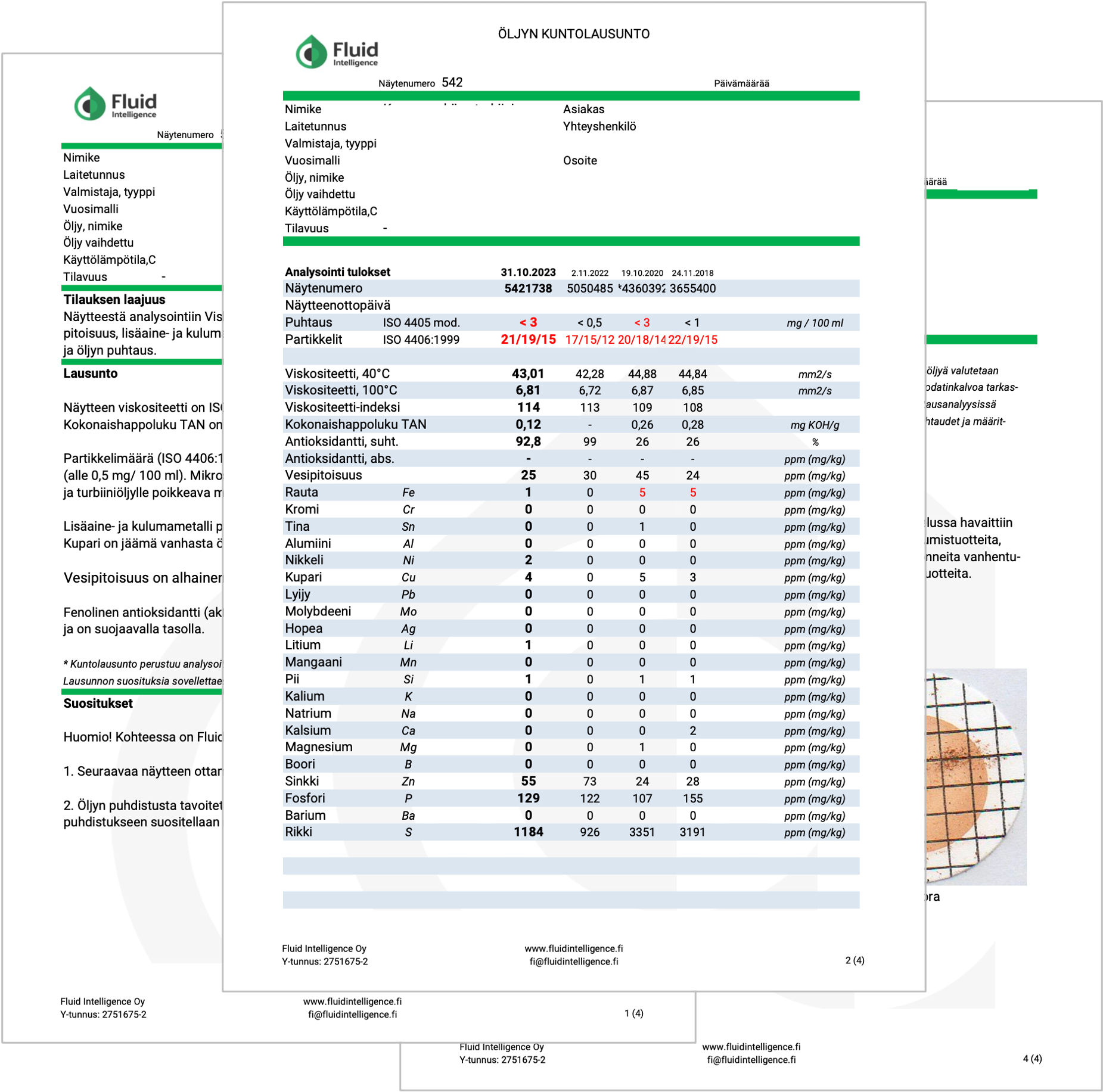

OIL ANALYSIS

Comprehensive oil analysis for a wide range of applications and operating environments. Our analyses cover lubricant chemical condition, cleanliness, wear metals, and contamination.

CLEANLINESS ANALYSIS

Raw analysis data alone is not always enough. Microscopic examination reveals particle origin, wear mechanisms, and the true nature of contamination.

PERFORMANCE STATEMENT

An expert assessment of the overall condition of the oil and the asset, including clear, actionable recommendations to support decision-making.

Comprehensive Oil Laboratory Services for Every Need

We provide a wide range of oil analysis services tailored to different applications and criticality levels.

Examples of analysis packages include:

Chemical condition of the oil (e.g. oxidation, additive health, viscosity)

Cleanliness and particle analysis

Water content and contamination detection

Wear metals and component-specific indicators

Application-specific analysis (hydraulics, gearboxes, turbines, engines)

Our services scale from standard routine analysis to advanced, application-specific investigations (e.g., hydraulics, gear systems, turbines, transformers, engines, and more).

TALK TO AN EXPERT ABOUT THE RIGHT OIL ANALYSIS SOLUTION

Call +358 50 308 6554

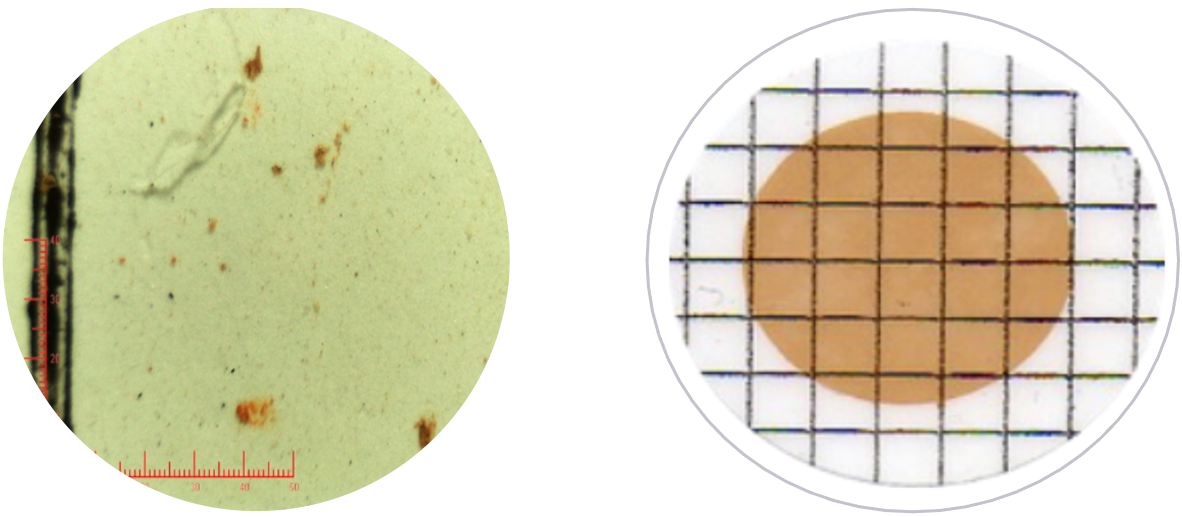

Microscope-Based Cleanliness Assessment – More Than Just Numbers

A particle count alone does not always tell the full story.

That’s why we provide a microscope-based cleanliness assessment alongside the analysis, where our expert evaluates:

Particle type and origin

Wear mechanisms

Contamination risks

This delivers significant added value compared to traditional laboratory reports and helps ensure corrective actions are accurately targeted.

ISO 4406: 18 / 16 / 13

Assessment based on microscopic analysis

In-Depth Condition Assessment – Not Just Results, but Interpretation and Conclusions

Based on the analysis results, we provide a comprehensive Performance Statement that answers key questions:

What is the true condition of the oil and the asset?

What risks are developing?

What actions are recommended – and why?

This turns oil analysis into a decision-making tool, not just a report.

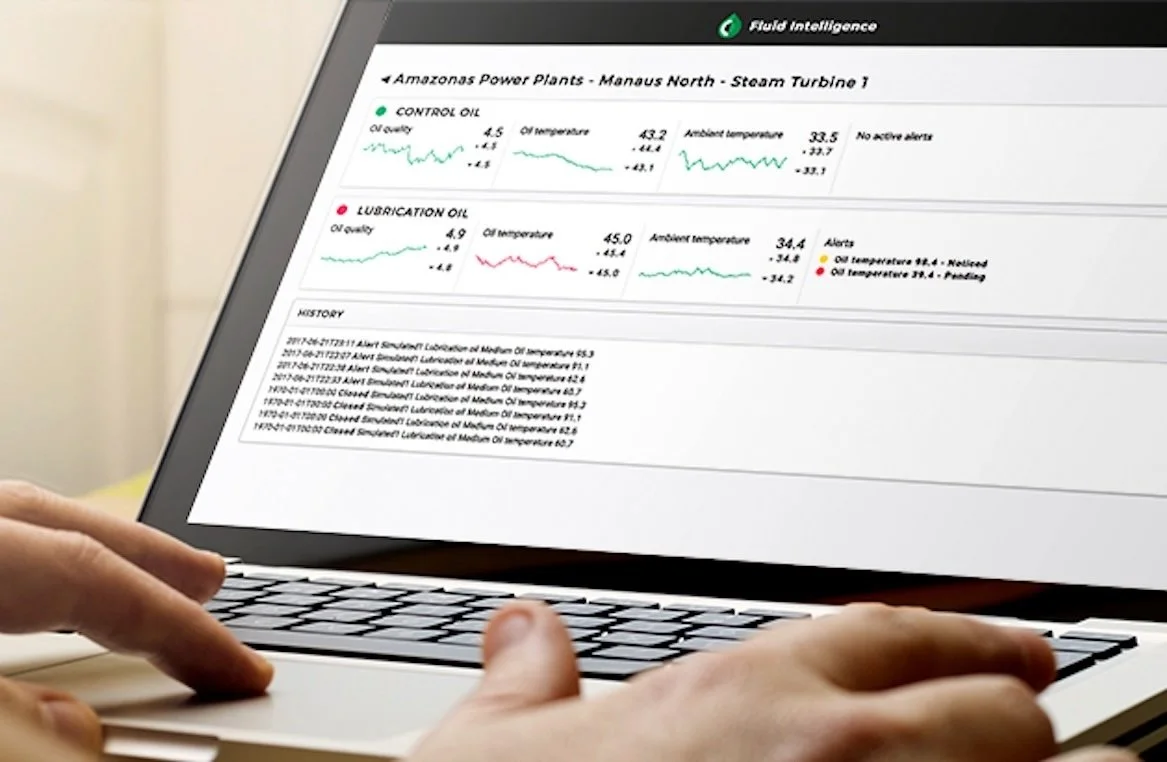

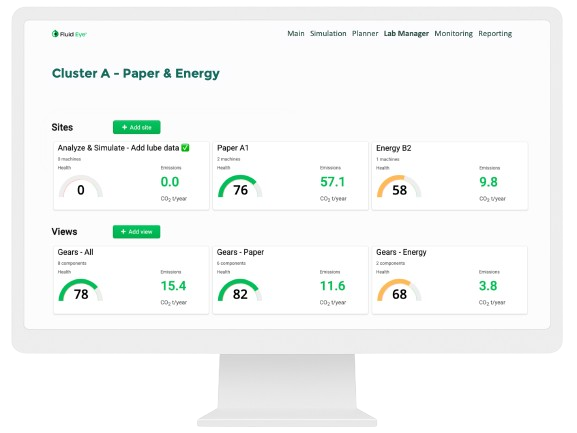

Fluid Eye® – Oil Analysis and Digital Data Management

Fluid Eye® – Oil Analysis + Digital Data Management

As a value-added service, oil analyses can be integrated into the Fluid Eye® platform, providing a comprehensive view of the lubricant lifecycle throughout its use – from sampling and analysis to maintenance actions, interventions, and reporting.

This enables:

Centralized storage of all laboratory results

A Health Score indicator for each lubrication point

Visibility at machine, line, plant, and enterprise levels

Automated action recommendations

Trend monitoring to identify issues early

Easy comparison between assets and fleets

This is a powerful alternative when real-time monitoring is not yet in place, but you want to go significantly beyond traditional laboratory services.

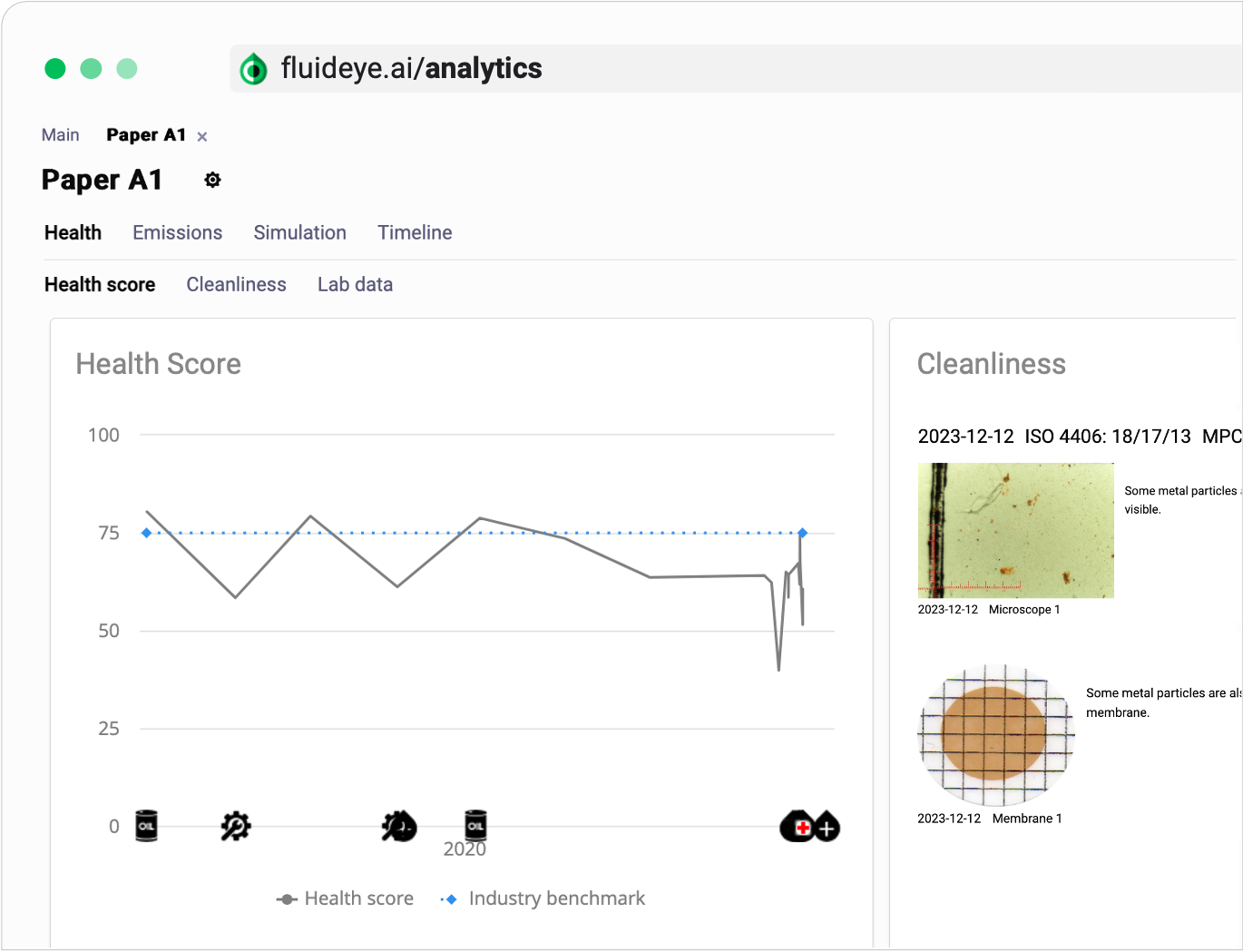

Events, Trends, and Reporting in One View

When laboratory results, events, and actions are combined into a single timeline, a comprehensive lifecycle view is created, supporting:

Optimization of the lubricant lifecycle

Maintenance decision-making

Cost efficiency

CO₂ emission reduction and reporting

Oil Analysis Is Part of a Broader Condition Management Strategy

Oil analysis provides valuable insight into lubricant condition and wear, but the real value is achieved when analysis data is combined with real-time condition monitoring and lubrication optimization.

Ready to turn oil diagnostics into performance insights?

Talk to our team to see how Fluid Eye® can deliver measurable results for your operations.