Lube Optimization

Extend oil life, boost reliability, cut costs and CO₂ - with contamination control, additives & expert care.

Why it Matters

From reconditioning to lifecycle optimization

Lubricants don’t just lubricate — they are one of the earliest indicators of machine health. Yet most oils are replaced far too early, or only after issues occur. This wastes money, shortens machine life and increases environmental impact.

Fluid Eye® Lube Optimization extends oil life through end-to-end lifecycle management — combining equipment, chemistry and expert know-how into one solution.

Key benefits:

Extend fluid life through contaminant removal and chemical stabilization

Reduce downtime by preventing varnish, water and additive depletion

Cut costs & CO₂ by extending oil life and minimizing waste

Boost reliability with expert analysis and tailored optimization projects

“Oil maintenance is a reliable method to ensure stable, trouble-free operation.”

Markus Lehti, Maintenance Engineer, Keravan Lämpövoima

How it Works

Three Pillars of Lube Optimization

Fluid Eye® integrates optimization directly into your lubrication strategy with three complementary service categories:

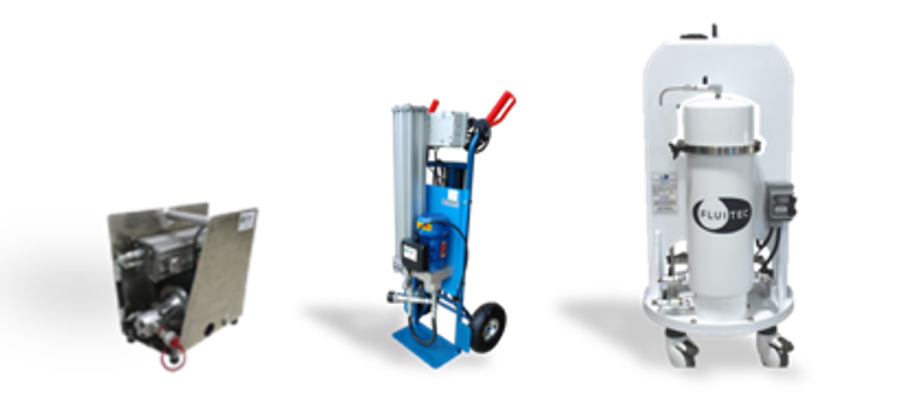

Contamination Control

High-performance oil re-conditioning units remove solid particles, water and soluble impurities (like varnish).

Continuous circulation or batch filtering

Real-time monitoring ensures success

Proven in turbines, hydraulics, gears and critical assets

Fluid Eye® NTF Mini, Mobile + VITA ESP II

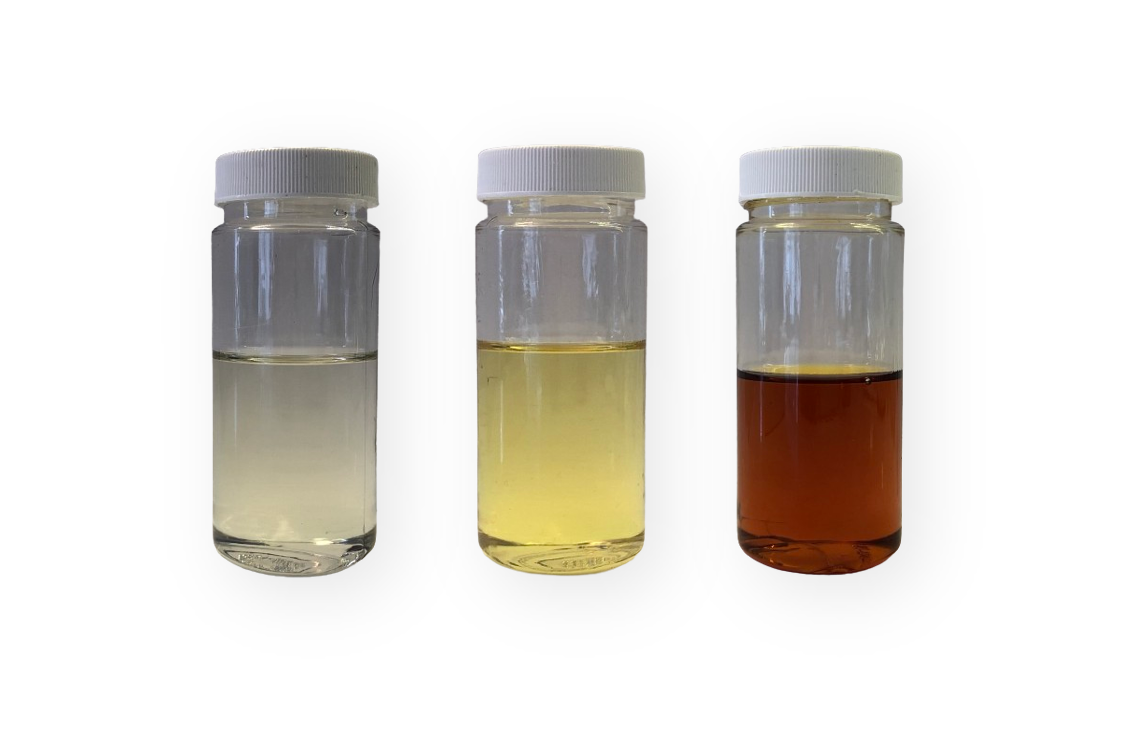

Chemical Enhancers

Additives and premium chemical solutions strengthen oil and extend its useful life.

Prevent oxidation and slow down aging

Restore additive package performance

Tailored blends for specific applications

Expert Services

Access hands-on expertise, lab analysis and site projects when you need it.

Oil flushing and purification projects

Site and emission audits

Lab Anaysis

Optimization consulting and tailored recommendations

Extend the Impact

From Savings to Sustainability

Lube Optimization does more than extend oil life — it drives performance across your operation:

Lower lifecycle costs by reducing unnecessary oil changes and disposal

Improve uptime & reliability with stabilized fluids and fewer failures

Support Net Zero goals by minimizing waste oil and CO₂ emissions

Ensure compliance with ISO standards and sustainability reporting frameworks

“

Explore how companies extended oil life by 3–5× while cutting lubrication costs

CUSTOMER STORIES ->

“Fluid Intelligence successfully executed oil flushing from circulation water pump system at Olkiluoto OL3.”

Stephan Bachmeier, Site Manager, Siemens AG

Ready to optimize your lubrication lifecycle?

Talk to our team to see how Fluid Eye® can deliver measurable results for your operations.