Lube Planning

Build a structured lubrication strategy - guided by real data and operational goals.

Why it Matters

Smarter lube planning starts here

Even top maintenance teams often need to rely on fragmented data, outdated plans or spreadsheets to manage lubrication. This leads to missed savings, inconsistent execution and unnecessary failures.

With Fluid Eye® Lube Planning, teams gain structure and control. By combining lab, machine and simulation data, you can build a targeted, measurable lubrication program that aligns with real-world conditions and business goals.

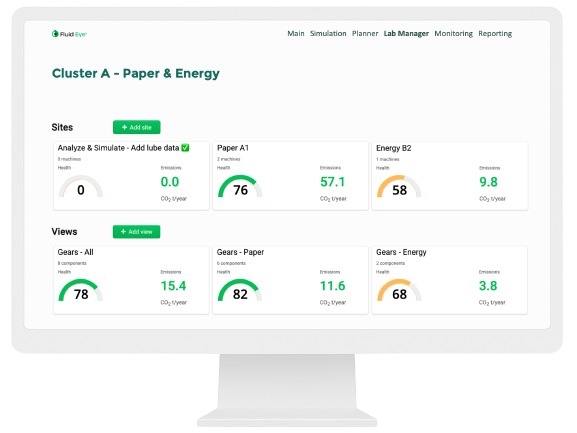

Align fluid programs across teams, assets and suppliers

Set site-wide lubrication targets with simulation-backed benchmarks

Replace manual plans with dynamic, data-driven guidance

Continue to Connected Oil® Monitoring →

How it Works

Structured programs. Dynamic tools.

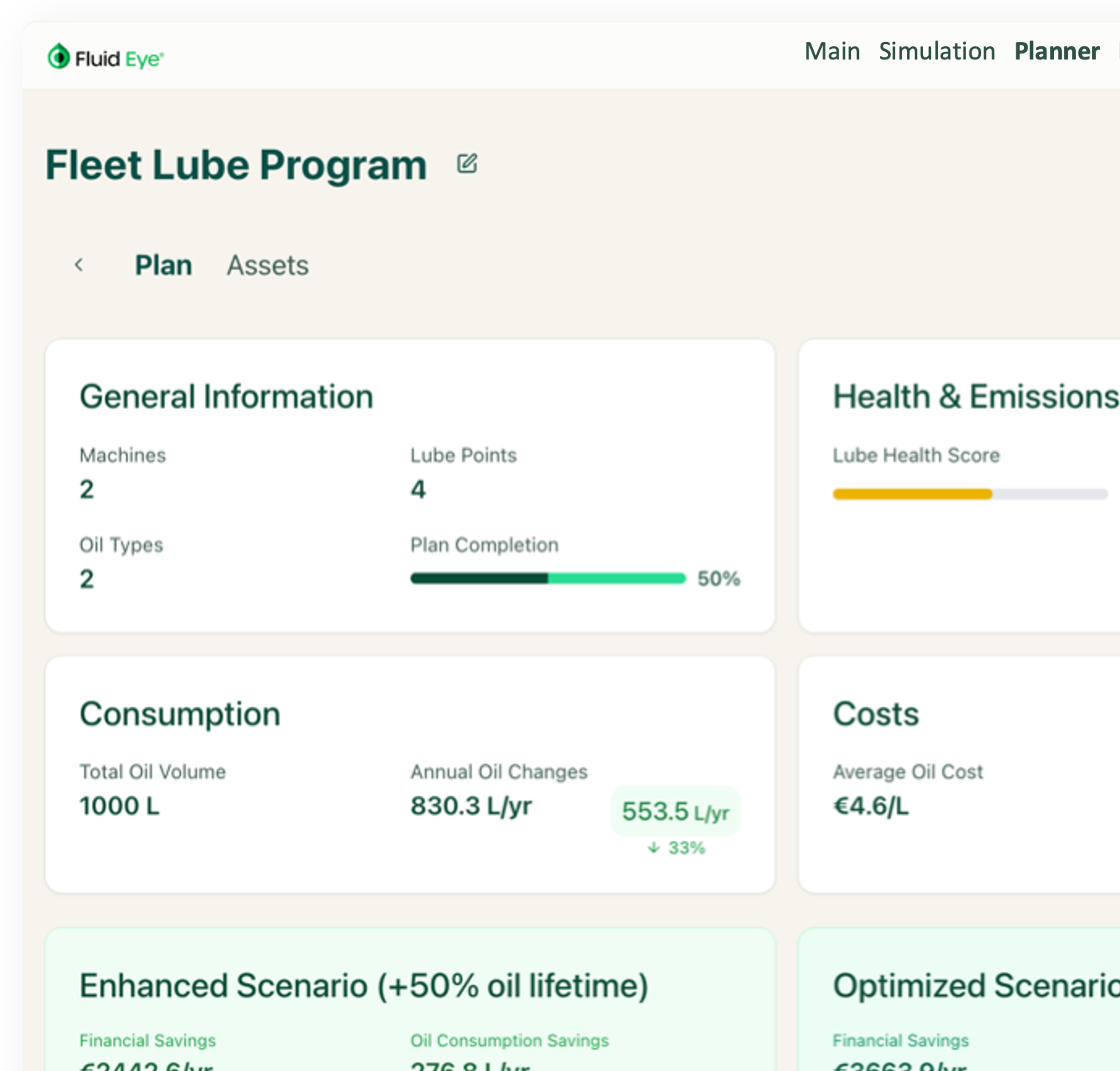

Program Builder: Connect machines, oil specs and lab schedules into one system

Target Manager: Set goals for fluid health, intervals, CO₂ or spend

Plan Tracker: Monitor implementation across teams and flag gaps in execution

Lube Planning integrates seamlessly with Value Simulation and oil monitoring — so strategies stay relevant as conditions evolve.

Extend the Impact

Extend the Impact – From Planning to Action

Planning isn't just paperwork — it's the foundation for better execution, reporting and results.

With centralized targets and tracked outcomes, your lubrication strategy becomes a living system that drives performance, cost-efficiency and sustainability.

Learn how Lubrication Plans are taken into action with Lab & Oil Data Management →

Ready to Build Smarter Lubrication Program?

Talk to our team to see how Fluid Eye® can deliver measurable results for your operations.