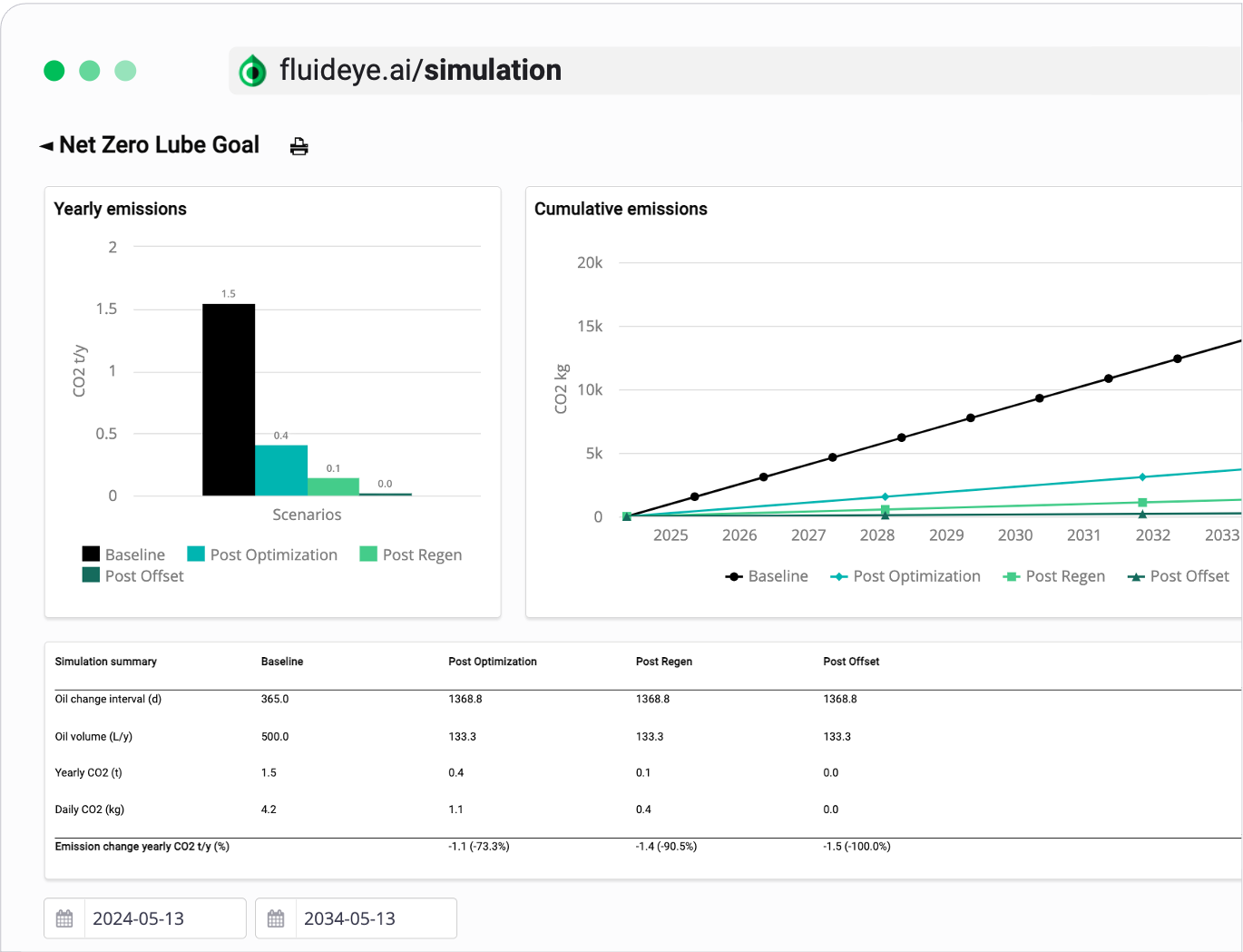

Value Simulation

Forecast cost, CO₂ and reliability impact - before a single drop is used.

Why it Matters

Reduce risk. Maximize return.

Even small changes in lubrication can have a big financial or operational impact. Simulation helps you make confident, data-driven decisions before implementation.

With Fluid Eye® Value Simulation, you can model the full lifecycle of lubrication choices — from fluid aging and emissions to TCO and failure risk. See the true business impact before committing a single resource.

• Reduce risk by testing alternative fluid and service scenarios

• Quantify costs and emissions before rollout with data-backed forecasts

• Align technical and business goals across teams

Continue to Lube Planning →

How it Works

Data driven forecasting tools

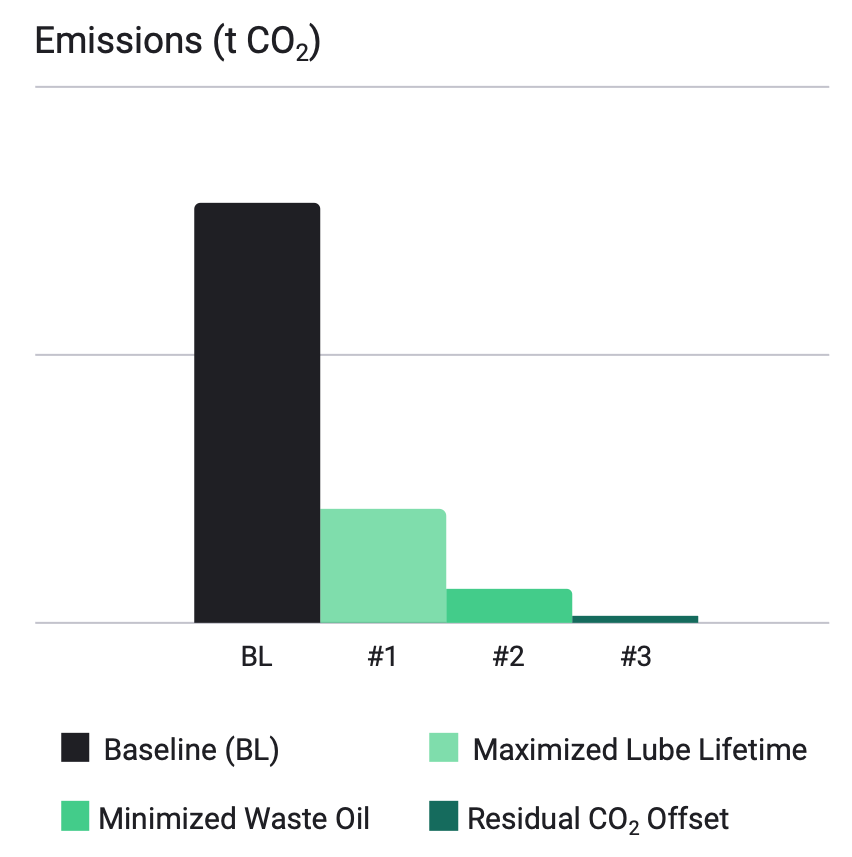

Scenario Modeling: Compare alternative oils, filters, or service levels

Cost & CO₂ Forecasting: Predict total cost and emissions across the lifecycle

Failure Risk Analysis: Estimate impact on uptime and maintenance intervals

Short simulations can be completed in minutes, with inputs pulled directly from your existing data and historical benchmarks.

Extend the Impact

From planning to proof

Simulation is not just a planning tool — it’s your evidence base for driving action.

Forecasted results become reference points for operations, procurement, and sustainability reporting.

Whether the goal is cost reduction, reliability, or Net Zero alignment, Value Simulation helps teams build the business case to act with confidence.

Explore how companies extended oil life by 3–5× while cutting lubrication costs

Ready to Simulate Your Lubrication Strategy?

Talk to our team to see how Fluid Eye® can deliver measurable results for your operations.