Net Zero Lubrication

Achieve Zero Downtime, Zero Waste and Zero Extra Costs - with smarter lubrication lifecycle management

Start your Net Zero journey

Net Zero Lubrication turns oil use into a driver of savings, reliability, and lower emissions. Powered by Fluid Eye®, we digitalize every step — planning, optimization, regeneration, and reporting — to deliver measurable impact across fleets, sites, and industries.

Maximize Oil Life

Extend lubricant life with smarter planning, monitoring, and optimization.

Minimize Waste

Turn waste oil into new value through regeneration and circular reuse.

Offset Residual CO₂

Compensate remaining emissions with certified, high-quality credits.

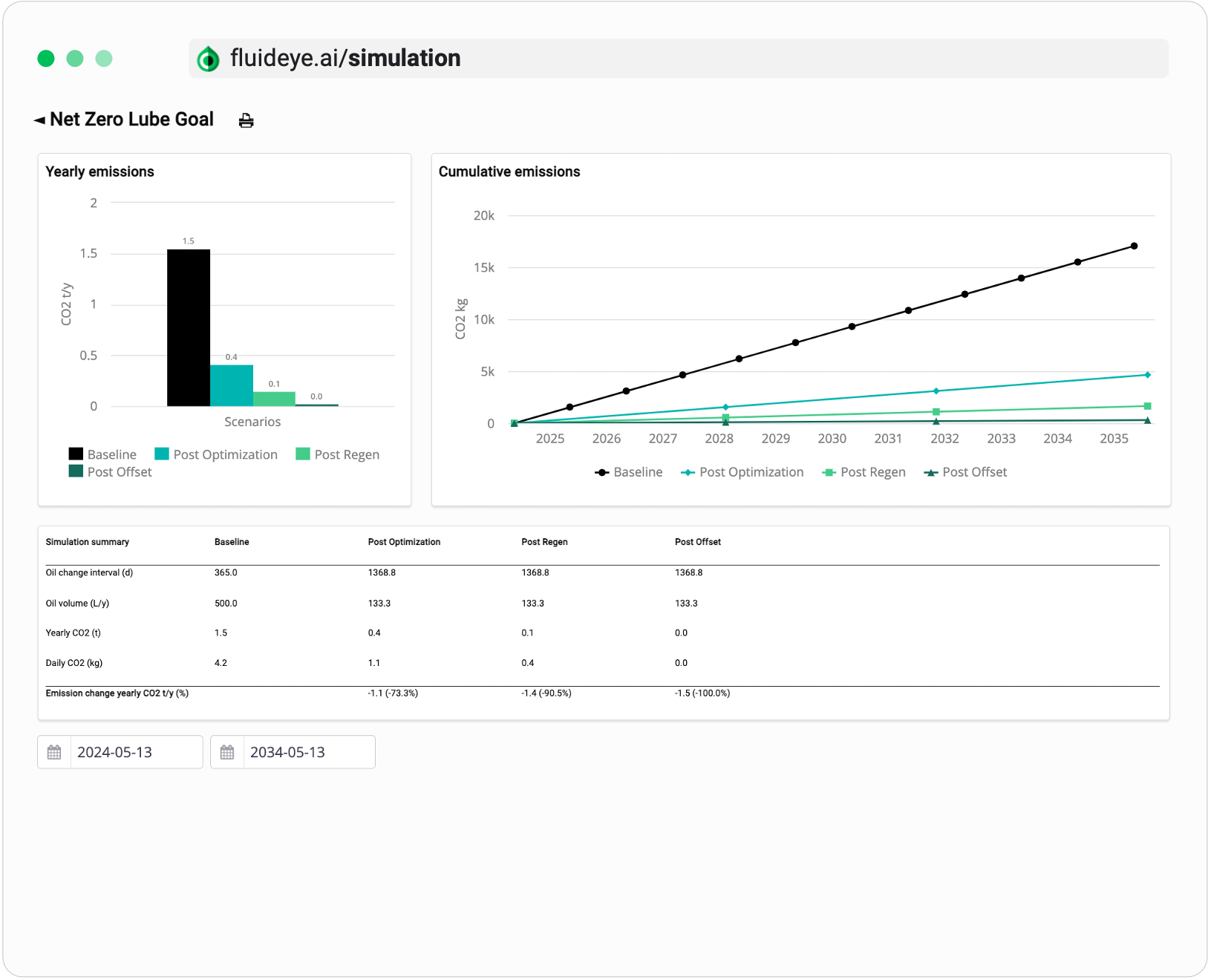

Impact of Net Zero Lubrication

Compared to baseline operations, Net Zero Lube delivers*:

Lube lifetime optimization

↓70-80%

Oil recycling by Regeneration

↓15-20%

Offset need for residual CO2

↓5-15%

* Fluid Intelligence Oy recorded field experience 2017-2024Maximize Lube Lifetime by Optimization

#1 Achieve major emission reductions

Prolonging oil life delivers the biggest impact on both CO₂ emissions and total cost of ownership.

With Fluid Eye® you can:

Run a Current State Analysis to identify savings potential

Optimize maintenance schedules with real-time and lab monitoring

Cut unnecessary oil changes, reducing both costs and emissions

Automate compliance and sustainability reporting

“The reduction of CO2 emissions by nearly 80% has not meant an increase in costs but rather nearly equal financial savings.”

Lauri Repokivi, Supervisor of L&T's Recycling Services

Minimize Waste Oil by Regeneration

#2 Get closer to Zero

Waste oil doesn’t have to end as waste. Regeneration creates circular value by turning used oil into high-quality base oil.

Fluid Intelligence enables companies to unlock circular value from waste oil by defining the right regeneration pathways and models for their operations.

With Fluid Eye® you can:

Benchmark regeneration options to align with your sustainability goals

Manage oil replacement and regeneration efficiently

Automate compliance documentation and reporting

Residual CO2 Offset by Credits

#3 Reach the Net Zero finish Line

Even after optimization and regeneration, a small share of emissions remain. Certified offsets ensure Net Zero is achieved credibly.

With Fluid Eye® you can:

Calculate final offsets accurately and automatically

Source high-quality, long-term storage credits (+100 years)

Generate transparent, audit-ready ESG reports

Ensure alignment with recognized international standards

Emission Management and Reporting compliance

Fluid Eye® ensures Net Zero Lubrication strategies are credible, auditable, and aligned with widely accepted sustainability frameworks.

Based on field results (2017–2024), customers achieve:

70–80% emission reduction from lubricant optimization

15–20% emission reduction from regeneration

5–15% covered through residual offsets

We select only trusted credit providers with long-term permanence so your Net Zero claims remain transparent and reliable.

* Baseline: current (usually time-based) oil drain intervals and maintenance practices