Oil Analysis, Real-Time Condition Monitoring and Optimization

Oil analysis and real-time condition monitoring are not alternatives to each other, but complementary methods.

Oil analysis and real-time condition monitoring are not alternatives—they are complementary methods. Oil analysis provides a deep view into lubricant and equipment condition, while real-time monitoring reveals anomalies the moment they emerge. When oil analysis, continuous monitoring and lubrication optimization are combined, you get a holistic model that improves reliability, extends oil life, and reduces maintenance costs.

In industrial maintenance and production, oil is one of the most important—and often underutilized—sources of insight. Oil analysis, real-time condition monitoring and lubrication optimization are frequently mentioned together, but their roles and use cases are easy to mix up.

The real value is created only when these three form a clear whole—not separate, disconnected actions.

In this article, we explain:

what oil analysis tells you

what real-time condition monitoring is best suited for

and how lubrication optimization is built on top of these.

Oil analysis – deep insight into lubricant and equipment condition

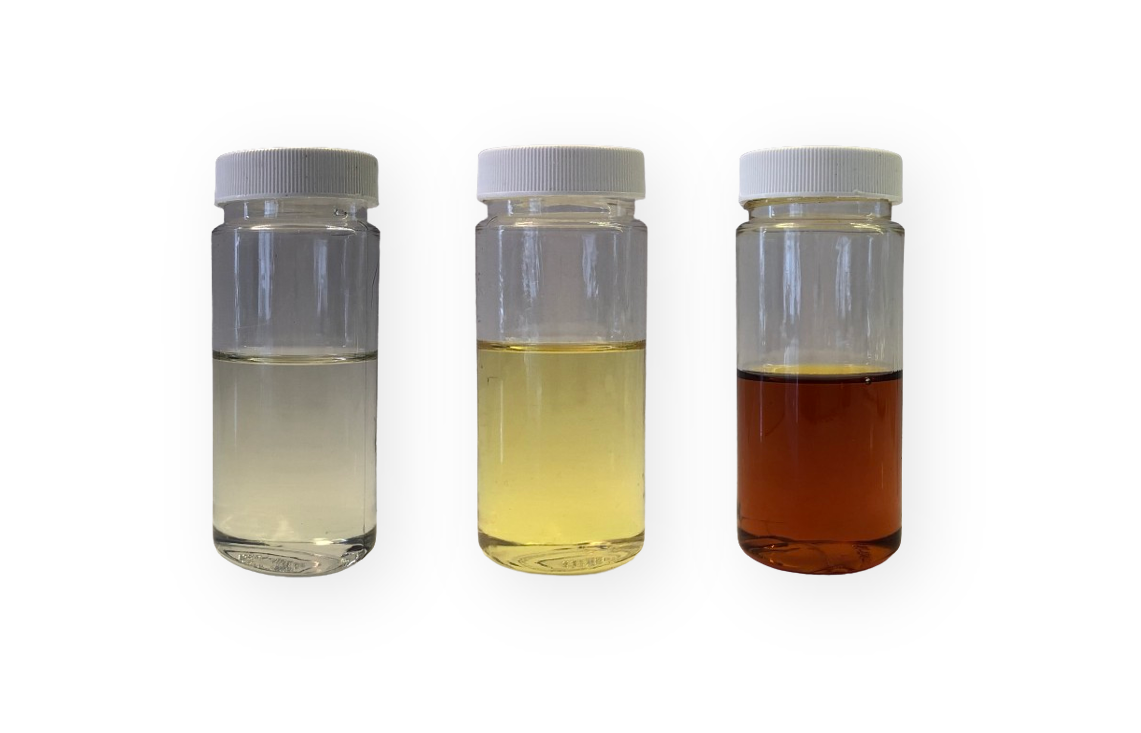

Oil laboratory samples

Oil analysis is the foundation of predictive maintenance. It provides a detailed view of oil chemistry, cleanliness and wear indicators.

Typically, oil analysis answers questions like:

Is the oil still fit for use?

Are there contaminants, water or abnormal wear in the system?

Are there signs of developing equipment failures?

Laboratory analysis is especially effective for:

periodic monitoring

assets where changes happen slowly

situations where accurate chemical information is needed

A single oil sample result, however, is only a snapshot. Without history, benchmarking and interpretation, its value remains limited.

Real-time oil condition monitoring – continuous visibility into critical changes

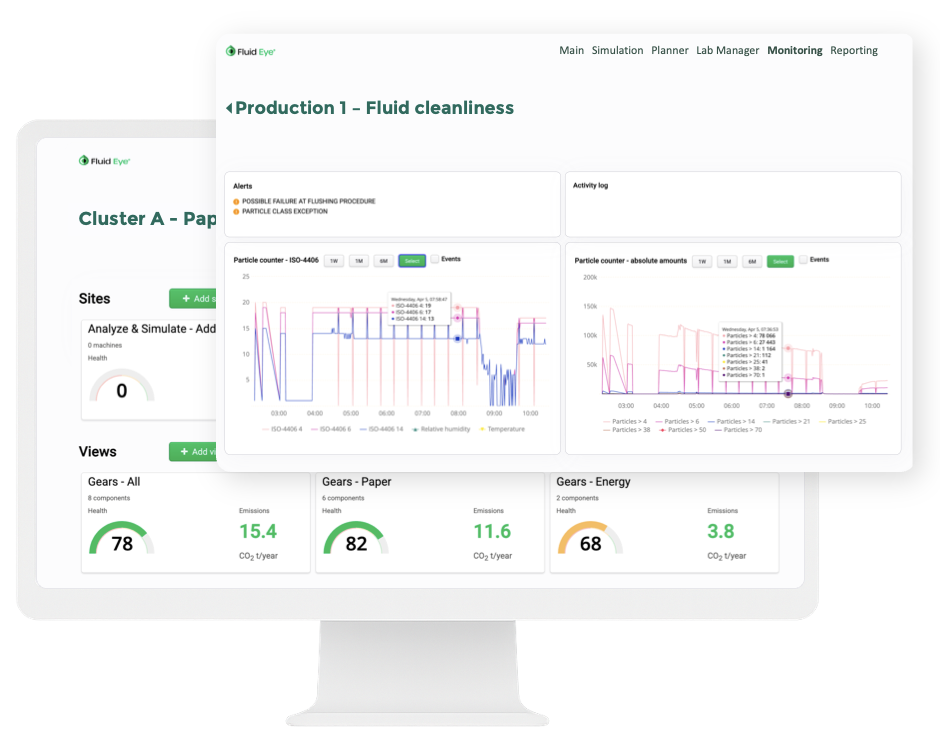

Fluid Eye® real-time condition monitoring dashboard and critical measurement points

Real-time oil condition monitoring complements lab analysis by providing continuous information about the condition of the oil and the system.

Online monitoring enables:

detecting anomalies as soon as they occur

fast response before damage or downtime

tracking the real impact of process changes in operation

Real-time monitoring is particularly well suited for:

critical assets and processes

applications with variable operating conditions

environments where risk management is central

Without analytics and context, continuous data can remain just a stream of numbers. Its value emerges when the information is connected to analysis and decision-making.

Lubrication optimization – turning analysis and data into action

Lubrication optimization is not a single action, like filtration or an oil change. It is an ongoing process that combines:

oil analysis

real-time condition monitoring

understanding operating conditions

timely, targeted interventions

In practice, optimized lubrication means:

longer oil drain intervals

higher equipment reliability

lower maintenance and energy costs

less waste and fewer emissions

Most importantly, decisions are based on evidence—not on fixed schedules or assumptions.

How do these work together?

The best outcome is achieved when oil analysis, real-time monitoring and optimization form a clear operating model:

Oil analysis creates deep understanding of oil and equipment condition

Real-time condition monitoring provides continuous visibility and early warnings

Lubrication optimization turns findings into actions and measurable value

Together, these enable a shift from reactive maintenance to a predictive, continuously improving operating model.

What if you have dozens—or hundreds—of assets?

Oil analysis and condition monitoring for a single machine are just the start. The real challenge appears when you need to manage multiple assets, production lines or sites.

Fleet/asset portfolio condition management requires comparable data, clear KPIs and centralized visibility. When oil analyses, real-time monitoring and optimization actions are connected at fleet level, decision-making shifts from reactive to strategic.

Read more: fleet management and multi-asset monitoring

Summary – not either/or, but a complete system

Oil analysis, real-time condition monitoring and lubrication optimization don’t compete—they work as a complete system.

Without analysis, there is no understanding.

Without monitoring, there is no ability to respond.

Without optimization, you don’t reach full performance.

When these are combined systematically, oil is no longer just a cost item. It becomes a strategic resource that improves reliability, extends component lifetime, reduces maintenance costs, and supports sustainability targets.

Want to see how this works in practice?

Explore oil analysis, real-time condition monitoring and lubrication optimization with Fluid Intelligence solutions.