Mastering the Lubrication Lifecycle

Introduction

In our previous article, we looked at why Net Zero Lubrication matters: the hidden trillion-dollar challenge of downtime, waste, and unnecessary costs, and why industries can no longer treat lubrication as a background expense.

Here, we move from why to exploring what the complete lube lifecycle looks like — and how it sets the stage for data-driven lubrication in the next step. To make Net Zero Lubrication possible, industries need to manage the entire lubricant lifecycle — from planning and monitoring, all the way to end-of-life recovery and transparent reporting. Lubrication is not just oil changes. It is a lifecycle system that connects operations, sustainability, and competitiveness.

The Complete Lubrication Lifecycle - From Plan to Impact

Full Lubrication Lifecycle model delivering Net Zero Lubrication by Fluid Eye®

Why Lifecycle Thinking Is Essential

Traditional lubrication practices are reactive. Oils are changed on fixed schedules regardless of condition, often leading to wasted resources and unexpected failures. Maintenance teams juggle fragmented data from lab reports, OEM recommendations, and manual inspections — rarely in one place, rarely in real time.

Meanwhile, new pressures are mounting:

Cost volatility in energy and raw materials — and the need to keep production and supply chains running without interruption — makes efficiency critical.

Regulation (CSRD in Europe, SEC climate disclosures in the US) demands verifiable emissions data.

Customers and investors expect proof of environmental and economic responsibility.

Without lifecycle management, lubrication remains a cost center. With lifecycle management, it becomes a performance platform.

The 3 Phases of the Complete Lube Lifecycle

At Fluid Intelligence, we define the complete lubricant lifecycle in three steps. This is the core of Fluid Eye® – The Operating System for Lubricants.

1. Plan with Insight

The lifecycle starts with data. By consolidating lab results, OEM specs, consumption history, and asset criticality into one platform, companies can finally see the full picture.

Fluid Eye® - Oil Data Management unifies all relevant oil data

Planning with insight means:

Unifying data into one clear system, where everything is easy to find and compare.

Simulating oil volumes, lifecycle costs, and CO₂ footprint before decisions are made.

Building a real lubrication plan and strategy instead of relying on rules of thumb.

This is how organizations move from calendar-based oil changes to condition-based, optimized planning — aligning lubrication with business strategy.

2. Perform with Precision

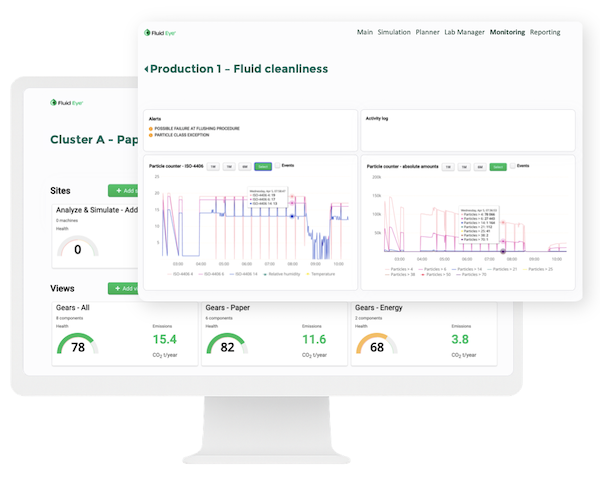

Once the plan is in place, execution must be precise. Monitoring oils and assets in real time enables proactive action before issues become failures.

Fluid Eye® & Connected Oil® Monitoring

Performing with precision means:

Monitoring condition continuously through online sensors and lab integration.

Analyzing risks early, from contamination to oxidation.

Optimizing oil life and machine reliability with filtration, additives, and other re-conditioning tools.

Instead of reacting to breakdowns, teams optimize performance every day.

3. Extend the Impact

Lubrication doesn’t end when oil is drained. Extending the impact means capturing value even at the end of the lifecycle.

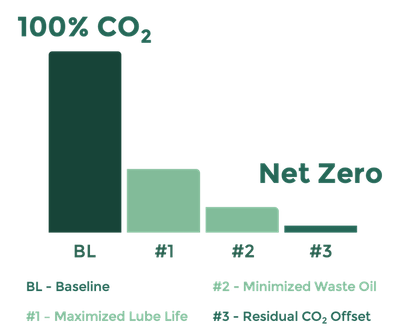

Minimize oil-based CO2 by Fluid Eye®

That includes:

Recovering and reconditioning oils to give them a second life.

Reducing waste streams, minimizing disposal costs, and offsetting remaining CO₂ with certified credits.

Reporting results transparently on costs, CO₂, and reliability — from machine to enterprise level.

By extending the impact, lubrication becomes measurable proof of cost savings, emissions reductions, and ESG commitment.

Real-World Benefits

When companies manage the complete lube lifecycle, results follow quickly:

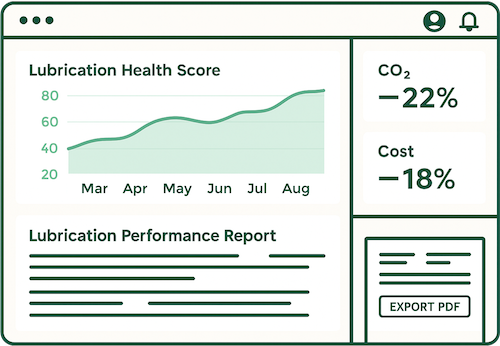

Fluid Eye® - Delivering Net Zero Lubrication

Oil life extended 3–5× in heavy industries, cutting both cost and environmental footprint.

Waste-to-value practices turn used fluids into new resources through recovery and regeneration.

Verified reporting delivers credible CO₂ reduction figures and lifecycle cost transparency — always audit-ready.

In one case, a crusher fleet extended its oil life by 4–5× with Fluid Eye®. This not only reduced downtime risk but also slashed waste oil handling and improved sustainability reporting.

What Makes Fluid Eye® Different

Most lubrication programs focus on single tasks: sampling, filtration, or oil changes. Fluid Eye® is different. It acts as an operating system, integrating the full lifecycle into one digital environment.

What this means in practice:

Consolidation: All lubrication data, from labs to assets, in one place.

Simulation: Predictive modeling of oil volumes, costs, and carbon footprint.

Execution: Real-time & lab monitoring, plus oil re-conditioning through filtration and additives, with alerts across fleets and plants.

Extension: Tools for recovery, emissions tracking, and enterprise-level reporting.

The result is a system where every liter of oil is tracked, optimized, and measured for impact.

Fluid Eye® - The Operating System for Lubricants

Why Now?

The industrial world is at a turning point:

Volatile markets force cost control.

Regulations demand transparency.

Competition increasingly rewards sustainability and reliability.

Ignoring the lubricant lifecycle means higher costs, hidden risks, and missed opportunities. Embracing it creates resilience, credibility, and a measurable edge.

Net Zero Lubrication isn’t a slogan. It is a practical path to Zero Downtime, Zero Waste, and Zero Extra Costs — achievable only by managing the complete lifecycle.

Conclusion & Next Steps

The Complete Lube Lifecycle transforms lubrication from a maintenance task into a strategic asset. By planning with insight, performing with precision, and extending the impact, companies unlock uptime, savings, and sustainability — all powered by Fluid Eye® – The Operating System for Lubricants.

👉 If you missed last month’s article, read it here: Net Zero Lubrication – Why It Matters

👉 In our next article, we will go deeper into Lube Lifecycle Data Management — how to consolidate, standardize, and turn lubrication data into a competitive advantage.

Learn more today by visiting our newly updated website: fluidintelligence.fi