Net Zero Lubrication - Why it Matters

Introduction

In heavy industries, lubrication has traditionally been seen as a background task — a cost line in the maintenance budget, something to fix when it fails. Yet this hidden activity determines whether production lines keep running or grind to a halt.

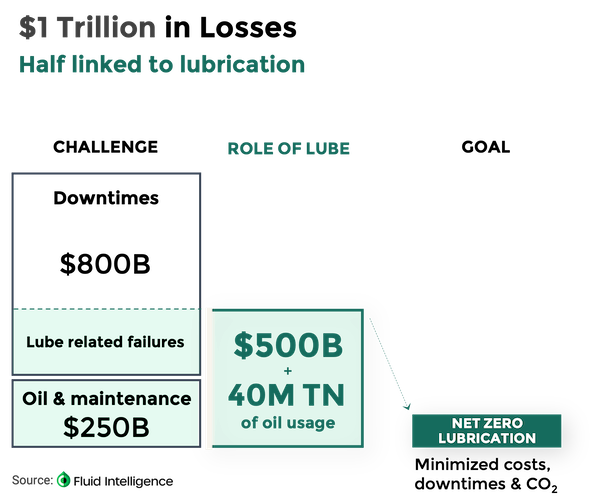

Every year, industries lose more than $250 billion in downtime caused by lubrication-related failures. Another $250 billion is spent on unnecessary oil changes, excessive fluid disposal, and reactive maintenance that could have been avoided. Together, these visible costs already approach half a trillion dollars annually. And they are just the tip of the iceberg: when adding the wider knock-on effects of production losses, equipment damage, forced shutdowns and waste handling, lubrication inefficiencies push industry costs closer to a trillion dollars. Looking even more broadly, when all sources of unplanned downtime are included, stoppages cost industries well over $1 trillion annually.

It is time to rethink lubrication not as a consumable, but as a strategic lever for industrial reliability and sustainability. That is what we call Net Zero Lubrication.

The Hidden Cost of Lubrication

Lubrication failures are rarely visible in boardroom discussions, but their impact is undeniable on the shop floor:

Picture 1. Role of Lubrication to Annual Industrial Downtimes and Costs

Unplanned downtime: Bearings, gearboxes, and turbines fail when lubrication quality is not monitored or managed. Production stops, deadlines are missed, and profitability suffers.

Waste and disposals: Fluids are often changed on a fixed schedule rather than based on condition. Perfectly good oil is discarded, driving up costs and generating unnecessary waste streams.

Hidden emissions: Every liter of lubricant has a carbon footprint — from production to disposal. Frequent oil changes multiply emissions that are rarely reported in sustainability metrics.

When these inefficiencies compound across global industries, they create a silent but enormous drain on resources.

Why Net Zero Lubrication?

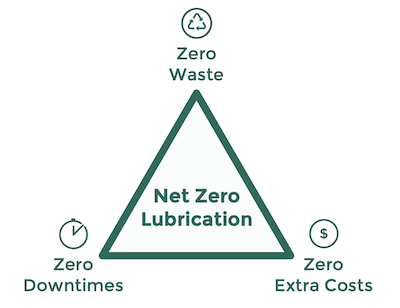

Picture 2. Net Zero Lubrication - key elements

Net Zero Lubrication is about setting a new performance standard. It aims to simultaneously achieve:

Zero Downtime → maximize uptime by preventing failures before they occur

Zero Waste → extend oil life, minimize disposals, and reduce emissions

Zero Extra Costs → cut unnecessary spending across the entire lifecycle

These are not just sustainability slogans. They are operational outcomes measured in reduced costs, improved reliability, and lower CO₂ footprints.

For example, extending oil life by 200–300% is not uncommon when monitoring and recovery systems are in place. That means fewer oil changes, lower purchasing costs, and less waste to treat. Similarly, predictive lubrication management can reduce downtime by double‑digit percentages — often worth millions of dollars annually in avoided losses.

Powered by Fluid Eye® – The OS for Lubricants

How can industries achieve Net Zero Lubrication in practice?

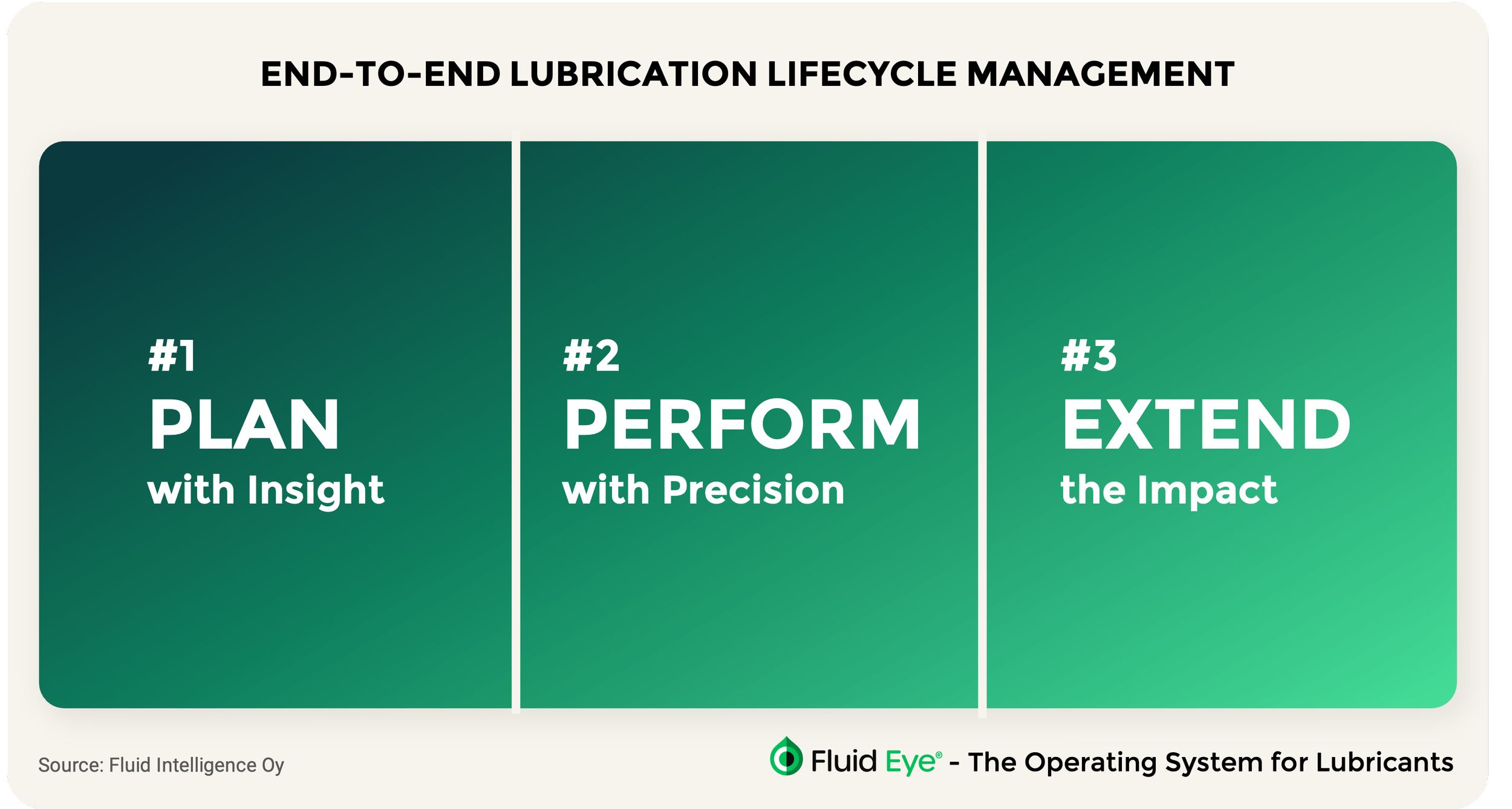

The answer lies in data and lifecycle management. Fluid Eye® – The Operating System for Lubricants – is designed to provide a full, digital overview of every fluid across the operation. Instead of scattered samples, spreadsheets, and guesswork, it offers a structured framework built on three steps:

Plan with Insight

Consolidate existing data into one platform to build transparency on current lubrication practices

Build a lubrication strategy based on actual equipment needs

Simulate oil consumption, lifecycle costs, and carbon footprint before making decisions

Optimize to perform

Monitor oil and equipment condition in real time

Detect risks before they escalate into failures

Optimize oil usage and extend drain intervals safely

Extend the impact

Recover and recondition fluids for reuse

Track emissions and prove reductions

Report lifecycle performance to management and stakeholders

Picture 3. End-to-end lubrication lifecycle model by Fluid Intelligence Oy

By combining these three steps, lubrication shifts from a maintenance afterthought to a performance platform that drives uptime, cost efficiency, and sustainability.

A Strategic Enabler for Industry

Global competition, ESG reporting, and the energy transition are pushing industries to deliver more with less. The ability to prove both economic and environmental results is becoming a differentiator in markets from steel and paper to logistics and energy.

Net Zero Lubrication enables exactly that. It provides measurable data points that connect operations with ESG strategies:

Scope 1 and 2 reductions: less energy lost in inefficient machines, fewer emergency shutdowns

Scope 3 reductions: lower oil consumption, less waste transport, fewer disposals

Economic competitiveness: reduced downtime and lower total cost of ownership (TCO)

In other words: lubrication is not only about keeping machines running. It is about building long‑term competitiveness in a resource‑constrained world.

Why It Matters Now

The industrial landscape is changing rapidly:

Energy and raw material prices remain volatile

Sustainability reporting (such as CSRD and SEC climate disclosure) requires transparent data

Customers and investors expect proof of environmental and financial responsibility

In this context, ignoring lubrication as a strategic lever is no longer an option. Companies that continue to treat oil management as a routine expense will fall behind those that turn it into a source of performance and advantage.

Net Zero Lubrication is not just a concept — it is a new operational standard. And given the scale of the challenge — a trillion‑dollar problem for global industry every year — the opportunity for improvement is equally massive.

Conclusion & Next Steps

Lubrication inefficiencies cost industries hundreds of billions each year in downtime, maintenance, and waste. But with Net Zero Lubrication, powered by Fluid Eye® – The Operating System for Lubricants, companies can turn this hidden challenge into a competitive edge.

Zero Downtime → reliability and maximum uptime

Zero Waste → longer oil life, less disposal, lower emissions

Zero Extra Costs → optimized lifecycle costs

In September, we will explore how to master the complete Lube Lifecycle — diving deeper into how to Plan, Optimize, and Extend.

Learn more today by visiting our newly updated website: fluidintelligence.fi